Computer Software for Steel Professionals

Structural Material Manager Free-Form vs. Shear-Cut Plate-Nesting Diagrams

Structural Material Manager's Plate-Nesting Module can produce two distinctly different types of cutting diagrams: free-form and shear-cut.

The free-form pattern is ideal when the equipment cutting the stock sheet uses a saw blade, water jet, flame, laser, plasma, etc. Any of those cutting methods, as opposed to shearing, need no restrictions concerning plate placement. No matter how the Plate-Nesting Module arranges the pattern, the equipment will be able to cut it.

The shear-cut pattern is one in which no reentrant cuts occur. That is, all cuts line up through the entire length and/or across the entire width of the stock plate. The reason: once a shear starts, it cannot stop. The shear must pass all the way through the stock plate on each cut. The shear operator may have to rotate the stock plate 90 degrees on the shear many times, but the Plate-Nesting Module guarantees that the pattern will definitely be shearable.

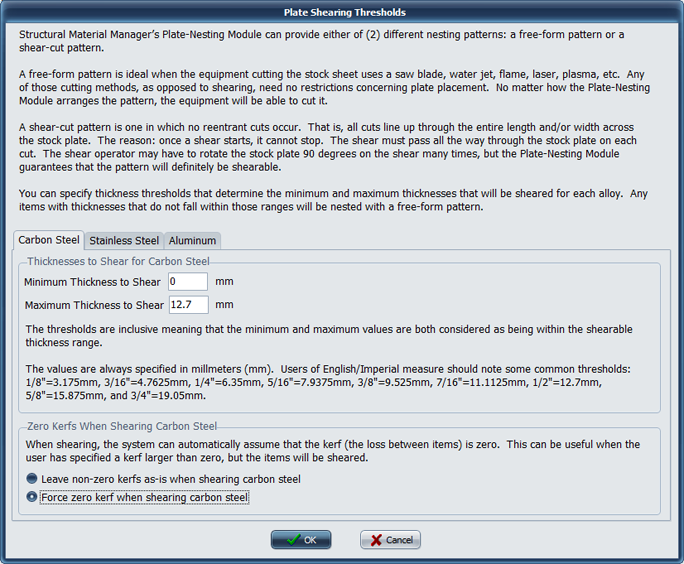

You can specify thickness thresholds that determine the minimum and maximum thicknesses that will be sheared for each alloy (carbon steel, stainless steel, and aluminum). Any items with thicknesses that do not fall within those ranges will be nested with a free-form pattern. The thresholds are inclusive meaning that the minimum and maximum values are both considered as being within the shearable thickness range.

The Plate-Nesting Module nests Plates, Checkered Plates and Bar Grating. The shearing thresholds apply only to Plates and Checkered Plates, as Bar Grating always uses a free-form pattern.

Minimum and maximum shearing thresholds are initially set at 0 when Structural Material Manager is installed. That is, by default, the system will produce a free-form nest. You must change those thresholds in order to activate the shearing feature. To bring up the dialog at which these thresholds are set, simply click the Shearing Thresholds button at the Nest Material dialog.

The thickness thresholds are always specified in millimeters (mm). Users of English/Imperial measure should note some common thresholds: 1/8"=3.175mm, 3/16"=4.7625mm, 1/4"=6.35mm, 5/16"=7.9375mm, 3/8"=9.525mm, 7/16"=11.1125mm, 1/2"=12.7mm, and 5/8"=15.875mm.

The screen below is the one at which shearing thresholds are set up for carbon steel, stainless or aluminum depending on which tab is selected:

To fully demonstrate the difference between the free-form and shear-cut patterns, E.J.E. Industries set up a job containing (2) groups of plates. The first group was 1/2" thick grade 304 stainless material, and the second group was 1/2" A36 carbon steel material. Other than the material grades, the plates in each group were identical. With Structural Material Manager configured to shear stainless material only up to 3/16" (4.7625mm) but carbon steel material all the way up to 1/2" (12.7mm), both possible nesting patterns resulted. The 1/2" stainless material used a free-form pattern, and the items were able to be cut with 100% efficiency from a single 4'-0 x 8'-0 stock sheet. The 1/2" carbon steel items used the more restrictive shear-cut pattern which resulted in an extra 4'-0 x 4'-0 stock sheet being needed in addition to the 4'-0 x 8'-0 sheet. In other words, the free-form nest achieved better efficiency since it did not have to be shearable, and the shearable nest sacrificed some efficiency in order guarantee shearability. To see the nested report as a PDF, click here.

Shearing is often assumed to be lossless in that no kerf allowance (the cut width) between items is necessary. When shearing, Structural Material Manager can automatically set the kerf to zero. This can be useful when the user has specified a stock plate as having a kerf larger than zero, but the shearing thresholds are later set so that the stock actually ends up being sheared. A pair of radio buttons labeled "Leave non-zero kerfs as-is when shearing" and "Force zero kerf when shearing" determine whether this automatic override is performed. Choose the former option if you do indeed wish to leave a kerf between sheared items, but the latter option is ideal if you want to assume all shearing operations to be lossless.

When saving the shearing thresholds, you'll be asked whether the changes should be saved as system-wide defaults. If you are nesting for your company"s own shop at all times, it is best to always save changes as the new defaults. The reason: your equipment and its parameters will remain the same for a long time.

If you are using Structural Material Manager to do contract estimating for various fabricators or are perhaps brokering jobs to be produced by any number of outside fabricators, different shearing values may be needed for different shops. In such cases, you'll want shearing thresholds to be job-specific, and you should not permit the changes to become system-wide defaults.